When Mike Barnes bought new tires for his 1997 Jeep Cherokee from Summit Racing, he had no idea that the increased traction of the Yokohama Geolandar M/T tires over the Cherokee’s former tires might expose a weak link in his driveline. When he found out from fellow club members that, in many cases, the enhanced traction of mud-terrains almost eliminated the need for selectable lockers, he became worried and decided to upgrade his front axles.

When faced with the decision of choosing between a tire that offers good mileage or good off-road traction, if traction is the choice it usually will come at the expense of extended tread mileage. That’s not the case with the new Geolandar M/T. The tire is constructed with a directional tread pattern for outstanding off-road grip and easier clean out to remove mud and debris. Plus, the tires have extra sidewall ribs and an advanced tread compound for added durability out on the trail, along with a step-block groove configuration to increase the surface area and improves drainage.

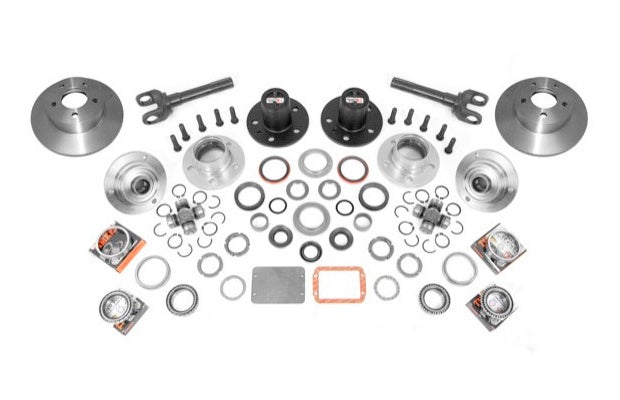

The great off-road traction provided from the Yokohama mud-terrains created an easily overlooked issue in regards to the 20-year-old OEM axles and u-joints that could be twisted or broken from the added stress on the trail. To avoid the possibility of future trail repairs or tow-strap pushing, Barnes decided to preempt possible problems with a chromoly front axle and manual (freewheeling) hub kit, and he decided to turn to Summit Racing for the one-stop shop. Alloy USA’s Manual Locking Hub Conversion Kit for ‘84-‘06 Jeep Cherokee/Wrangler XJ/YJ/TJ/LJ models (P/N: ALY-12198, $1,587) is the perfect kit to convert a Dana 30 to freewheeling, with new very strong front axles, U-joints, bearings, seals, and brake rotors thrown in. Please make note: This kit is for the Dana 30 axle only, and it won’t work on a Rubicon Dana 44 axle.

The Alloy USA chromoly axles make a lot of sense, but why add manual hubs to your front axles? For several reasons, especially if you’re a commuter and the Jeep is your daily driver: Improved highway gas mileage, reduced front driveline wear and tear, easier steering effort, and some say reduced front tire wear. When the hubs are disengaged the front tires merely spin on the wheel bearings. The front axles, the front ring and pinion, and the front driveshaft are no longer spinning. They now just ride there, waiting until you engage the hubs and shift into four-wheel drive.

For decades, four-wheeler manufacturers offered optional freewheeling hubs—some manual and some automatic—which were nearly always accepted on the option list. Then full-time four-wheel-drive transfer cases became all the rage, but they were gas guzzlers and weak links when it came to the more extreme trails, so enthusiasts quickly went back to selectable transfer cases. However, in most cases, the freewheeling hubs had gone the way of wind-wings and were lost in the process. Nowadays, hubs on new vehicles are few and far between—found almost exclusively on large, heavy-duty trucks.

Having learned to wheel in military Jeeps—I stuck a Jeep for the first time in 1958—I was totally unfamiliar with selectable hubs when I first started Jeeping as a recreational activity. In the early ‘60s, after chasing a dirt bike up and down trails for about two hours in a stock 1946 CJ-2a—no top, no doors, no roll bar, no seat belts, and the windshield removed—I stuck it in a deep ravine. We dug out the rear bumper and moved to the front bumper when I noticed the big chrome things in the middle of the front wheels. Since its lever was marked “2WD” and “4WD,” I twisted it to “4WD,” jumped in the Jeep and drove easily out of the ravine. I’ve been a freewheeling hub fan ever since!

Installing this conversion kit is not an easy two-hour task that anyone can do at home. You’ll need sufficient experience, a full set of hand tools (including a good torque wrench that measures foot-pounds), and a floor jack and jackstands (or a lift). If you know what you’re doing, the kit will take you six to eight hours to complete, and you may need a friend to assist. Your first step is to thoroughly read the entire set of installation instructions. The second step is to carefully check the package’s contents against the content list on page 8 of the instructions. Since the bearings and bearing races are so similar—as are some of the other components—you may want to write the IDs on all the parts (or their envelopes) with a Sharpie as you check them against the list (it’ll save you a lot of time during the install). Third step, read the instructions again.

Your Privacy Choices

Your Privacy Choices